Canadians in Colombia

Live | Work | Building a Coffee Farm

Jardin Antioquia Farm to Table – Seed to Cup

Coffee Production

May 2021

- 11.5 million 50 kilo bags – 3rd highest in the World

- 5 Steps to Coffee Production in Jardin Colombia

- Who Wins in the Coffee Game?

Hint.

Not the farmer!

In this post I’ll focus on the steps from planting and cultivating, to selling the bean to the Cooperativa in Jardin, Antioquia. I will write about what happens to the coffee after it leaves Colombia in subsequent posts.

Note: Colombia’s average annual coffee production of 11.5 million bags. It is the third highest producer of coffee in the world, after Brazil and Vietnam, though highest in terms of hand picked arabica beans that grow in Colombias ideal growing conditions at 1500-1800m.

What I will describe here is what you will see and experience during a Finca Mariposa Farm to Table – Seed to Cup coffee tour with Daniel Rendon.

.

5 Steps

Once the varietal is selected and the seedlings are planted it requires 2-3 years for the plants to mature enough to begin producing harvestable cherries. A coffee plant has lifecycle up to 7 years before it needs to be replaced with a new seedling to begin the process all over again.

Harvesting

The fruit, called the coffee cherry, turns a bright, deep red when it’s ripe and ready to be harvested. In most countries there is one major harvest a year. In Colombia there are two flowerings annually. A main and secondary crop. Because the land is so mountainous and steep in Jardin Colombia all the coffee is picked by hand through a very labor-intensive process. Pickers rotate among the coffee plants every eight to 10 days during the harvest period, choosing only the cherries which are at peak ripeness. A strong picker – known as a “bomba” – picks an average of 50kg of coffee cherries a day.

Processing the Cherries

At Finca Mariposa we use the wet method for processing the cherries. First, the freshly harvested cherries are passed through a pulping machine to separate the skin and pulp from the bean. With the pulp removed the bean is dried with only a light parchment skin remaining. At this stage the quality of the bean starts to be revealed. In the water the beans are naturally separated by weight as they pass through several channels. The lighter beans float to the top (lower quality), while the heavier ripe beans sink to the bottom (higher quality). After separation, the beans are allowed to lightly ferment. Depending on a combination of factors — such as the condition of the beans, the climate and the altitude — they will ferment for 12 to 48 hours to remove the slick layer of mucilage (called the parenchyma) that is still attached to the parchment. When fermentation is complete, the beans feel rough to the touch. The beans go through a final rinse and are ready for drying..

Drying the Beans

The pulped and fermented beans must now be separated into high and low quality beans and dried to approximately 11% moisture to properly prepare them for storage.

These beans, still inside the parchment envelope (the endocarp), are sun-dried by spreading them onto large drying tables where they are turned regularly jn the sun. The dried beans are known as parchment coffee and remain in classic “sisal bags” until they are graded and readied for export.

.

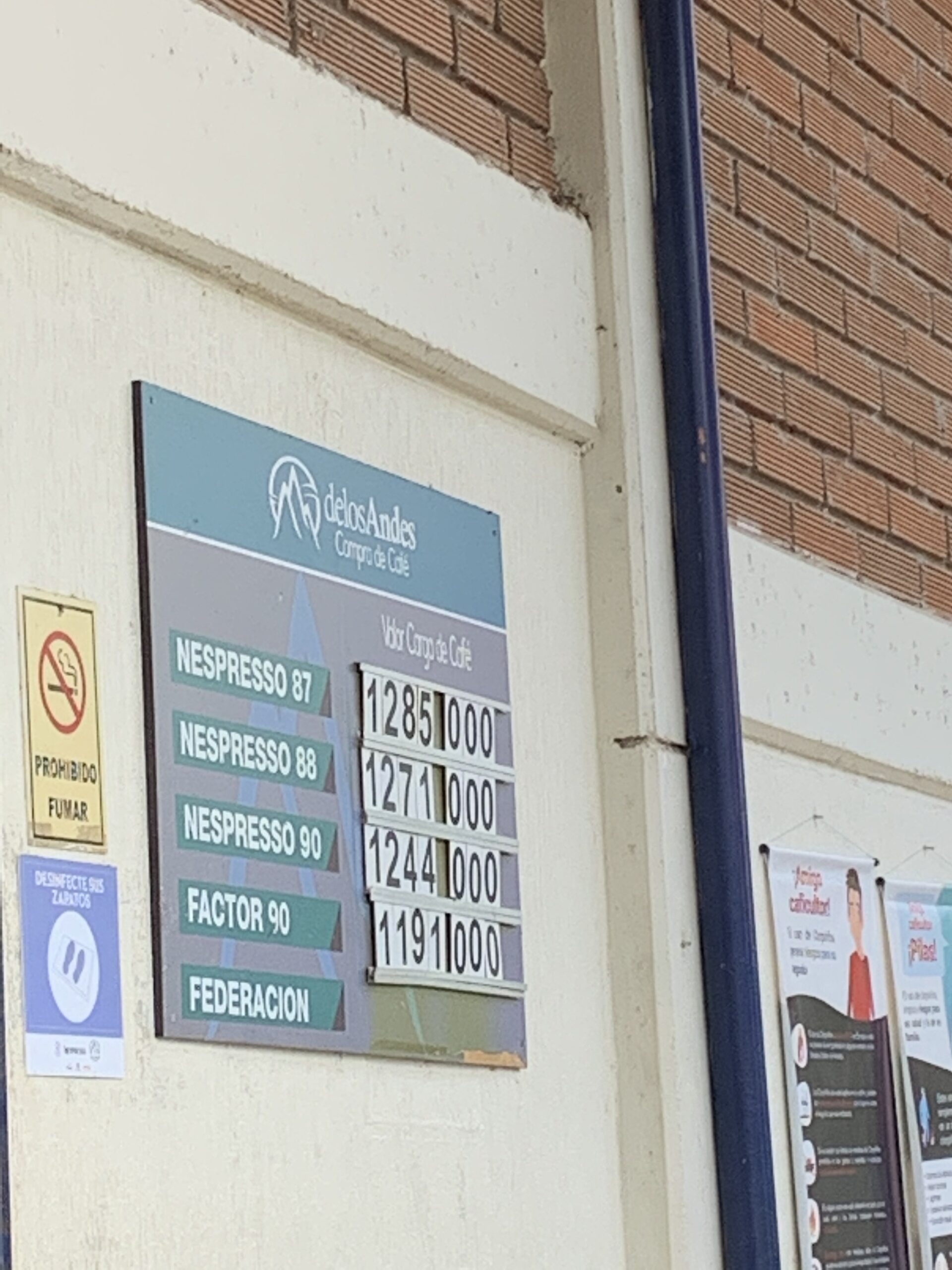

Grading and Sorting

Grading and sorting is done by size and weight, and also examined visually at the Cooperativa for color flaws or imperfections. The coffee master at the Cooperativa weighs a standard number of beans, examines them carefully for unacceptable size or color, over-fermentation or insect-damage. Once the quality is determined the grower is paid based on the grade of their coffee. This is fascinating step in the process to experience. Like all farmers around the world with crops to be sold, this is when the fruits of their labor are realized and the quality of their land and farming techniques are revealed.

.

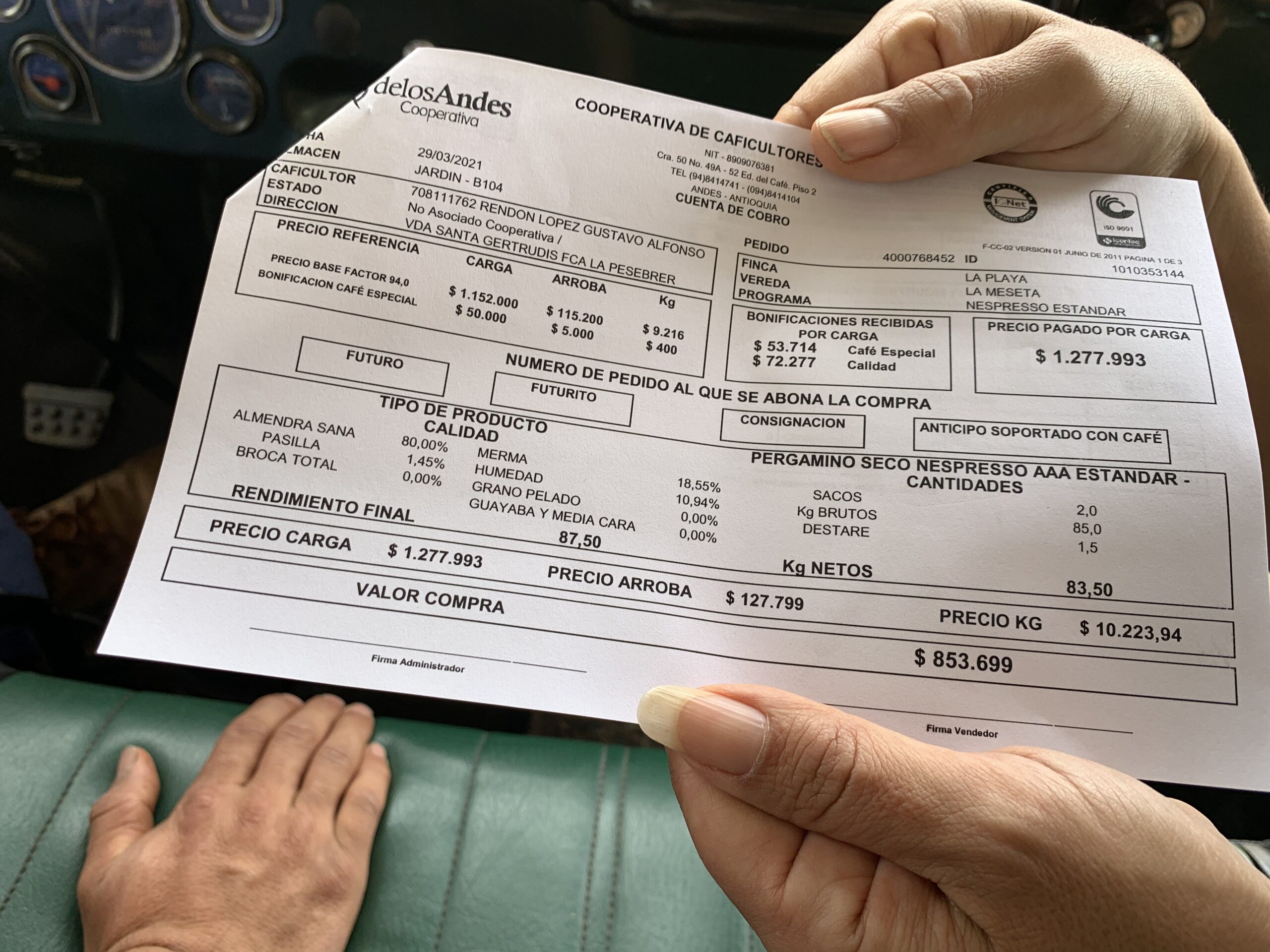

As you can see from the document above. 83.50 kilograms or 184 lbs of green coffee netted us $853,699COP or +/- $231.71USD. Green coffee expands by about 30% when it is roasted so the final number of pound that can be sold at the retail level would equal approximately 239.20 Ilbs. Conservatively retailers price a bag of premium quality beans at $18.00USD.

The producer after 2 years of cultivation, picking and processing earns approximately $231USD for 83kg of premium coffee. The retailer might add another 30% to buy and roast the beans in North America.

In round numbers that will vary by region the retailer can net between $3600 – $4000USD after costs.

So, when roasters and retailers talk about “fair trade” or “sustainable farming” or even “organic farming” in most cases the farmer – the producer – who puts their heart and soul into producing a magnificent bean barely breaks even after costs of cultivation and production. The global coffee trade is a $200+ billion market.

Too better understand the economics of this vast global supply chain hit the link below. And please remember, the next time you enjoy a cup of great coffee from Colombia the grower who shoulders all the risk of climate change, pests and fluctuating global commodity markets (without any centralized price controls like oil) earned about $0.07 of that cup.

https://www.visualcapitalist.com/the-economics-of-coffee-in-one-chart/